Collie Green Steel Mill

Western Australia’s first green steel mill and the cleanest and most efficient in Australia

FID 2024, Operational 2026

WA's first steel mill is expected to be operational in 2026

Green Steel of WA is pleased to announce that we are in the advanced stages of development and proceeding towards a final investment decision for Western Australia’s first steel mill.

The Collie-based green steel recycling mill will convert Western Australian scrap steel into rebar for local and international consumption. The plant will be WA’s first steel mill and Australia’s first green steel mill.

Construction of the plant is expected to commence in late 2024, with early operations beginning in 2026. The mill will be located in Collie, 220km south of Perth.

The current phase of the work to take it through to final investment decision has been part-funded by $2.7M of grant support from the WA Government through the Collie Futures Fund, administered by the Department of Premier of Cabinet (DPC) and the South West Development Commission (SWDC).

Current works include applications to local government, electricity network, and environment studies, as well as working with potential mill contractors to allow the project to switch rapidly into construction.

First steel is currently planned for 2026.

Green Steel's Bob Cowan, Danieli's Nicola and former Premier Mark McGowan shake hands at a funding announcement in Collie.

Cleanest and most efficient steel mill in Australia

Using the latest in continuous rolling and casting technology running on renewable energy, the plant will be Australia’s most efficient and environmentally friendly steel mill.

Danieli's frost-proof mini mill in Florida uses similar technology

Project at a glance

Project

Green Steel Recycling Mill

Technology

Electric arc furnace steel mill powered by renewable energy

Size

400,000 tons per year

CO2 emissions abated

562,000 tons per year

Investment size

$400 million

Jobs created

200+ local long-term jobs, 2000+ indirect jobs, 600+ construction jobs

Feedstock source

WA scrap steel

Electricity source

Renewable electricity

Product type

Long steel products (rebar/rod)

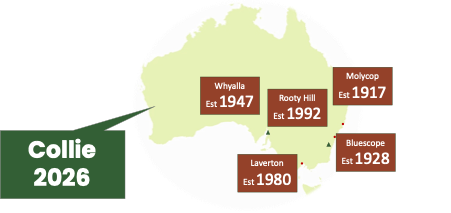

First new steel mill to be built in Australia in more than 30 years

Australia has not built a new steel mill in over 30 years.

As a result, Australia’s fleet of ageing steel mills are likely to face higher costs as they are old, highly emissive, and virtually impossible to decarbonise.

This, combined with Carbon Border Adjustment Mechanisms(CBAM), is expected to lead to an overall increase in the price of steel in Australia.

The Green Steel team is working closely with the Western Australian government to make local steelmaking a reality

Local investment, local employment

With a total investment of up to $400M, the project will create more than 200 long-term jobs in Collie directly and around 2,000 jobs through associated activities.

In addition to creating a credible opportunity for the transition of one of WA’s coal and industrial townships, the project is the company’s first step towards creating a genuine steel manufacturing industry in Western Australia.

Collie’s highly skilled industrial workforce was a key factor in the choice of plant location. Green Steel is fully aligned with Collie’s Just Transition Plan and is working closely with the government, local stakeholders, workers and their representatives to develop and implement an effective, fair and transparent worker training and transition plan that will benefit both workers and GSWA’s operations alike.

Green Steel is committed to working with local businesses and contractors to ensure the local economy and community benefits.

Clean and green steelmaking

Steel is the most recycled material on earth due to its ability to retain its intrinsic properties over multiple cycles. In fact, recycled steel makes up around 30% of all steel production globally.

Steel recycling is preferable to producing steel from iron ore as it requires far less energy and thus produces less pollution as well as eliminating costly landfilling.

Green Steel’s Collie mill will use an electric arc furnace to smelt scrap steel, allowing it to be cast and rolled into new steel products.

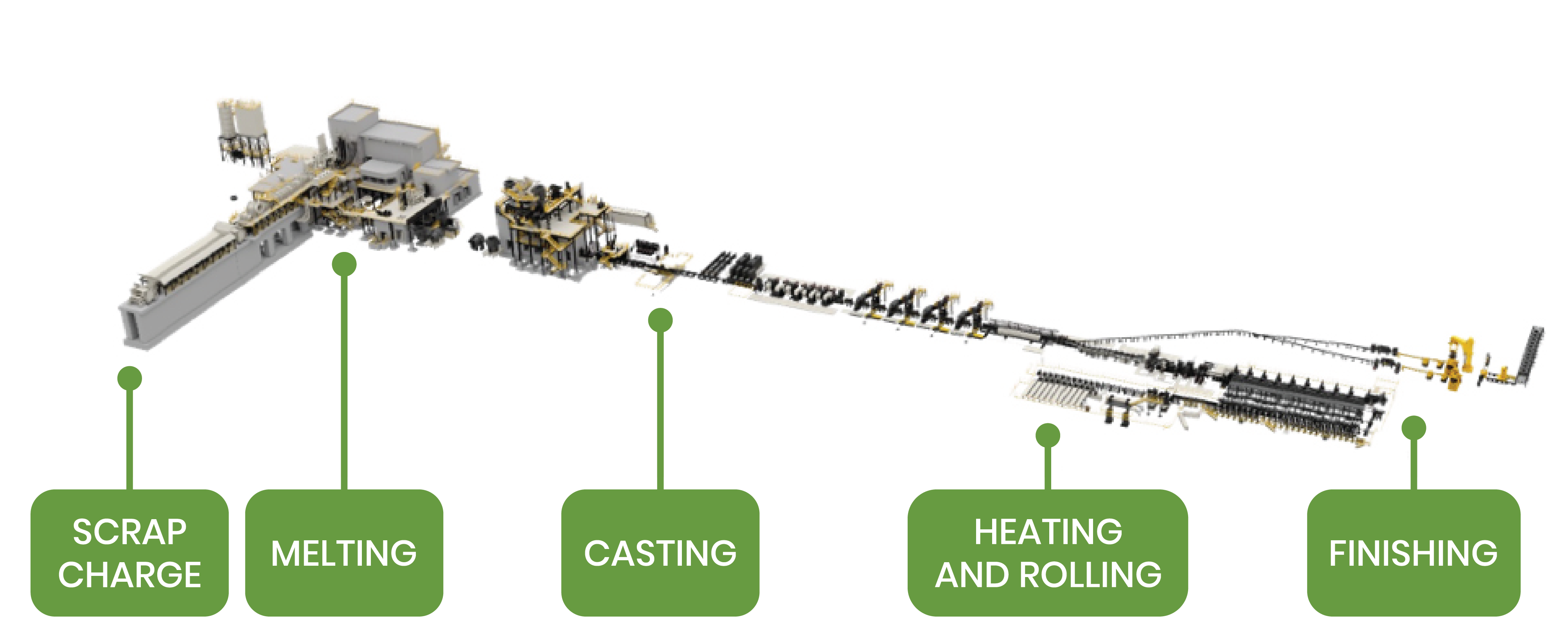

The steelmaking process can be broken down into the following main areas:

- Scrap steel handling and processing where scrap steel is sorted and cut into suitable shapes to be fed into the electric arc furnace

- Smelting and refining where scrap steel is melted in the electric arc furnace and impurities removed

- Casting where a continuous caster is used to form a continuous strip of semi-molten metal

- Rolling and cutting where the hot steel is rolled and cut into final shapes

Unlike conventional blast furnaces that run on coal, electric arc furnaces use electricity to melt steel. Our process consumes far less energy than making steel from iron ore.

In addition, our advanced inverter-based system is the only one able to operate stably on renewable power, producing virtually no carbon dioxide emissions. Advanced air cleaning and dust capture technology ensures the process produces almost zero particulates or other noxious gases.

Running on renewable power, Green Steel’s Collie mill will be the cleanest steel mill in Australia.

Minimal noise emissions

Green Steel’s plant is designed to minimise noise emissions. At the site boundary, the sound emitted will be comparable to normal conversation or background music and quieter than a typical office.

Electric arc furnace steel mills are so quiet, they have been able to be located close to residential and commercial areas with little to no impact, sometimes with houses as close as 500m from the plant.

Collie, a town in transition

Collie is an established industrial hub, home to a diverse range of industries including energy generation, mining, manufacturing and primary industries.

Collie is just a two-hour drive from metropolitan Perth and just 50 kilometres from the nearby City of Bunbury and the deep-water Port of Bunbury. The Busselton Margaret River Airport is situated 100 kilometres south-west and has recently been upgraded to cater for large commercial aircraft and interstate services.

Traditionally a coal mining and energy generation hub, Collie’s local economy is diversifying, with increasing investment in clean energy, mineral processing, manufacturing and agribusiness. Tourism is also growing in the region, which boasts impressive destinations such as Wellington National Park, Lake Kepwari and world-class mountain bike trails.

The picturesque Collie region boasts an attractive natural environment and connected residential community, supported by a full range of community services and affordable housing.

The Collie region provides a healthy, safe and secure environment to do business, with the growth of existing and new industries, robust supply chains, a large and highly skilled workforce and excellent transport and energy infrastructure.

The Western Australian Government, industry, community and unions have combined to form the Just Transition Working Group, which is working to ensure Collie’s long-term economic prosperity.

With the announcement of the phased retirement of the remaining coal-fired power stations in Collie, the State Government has unveiled a Collie Transition Package worth $547.4 million to support future job creation in the area. This package brings the State Government’s total investment in Collie to over $662 million.

Additionally, approximately $300 million of the funds will be allocated to the decommissioning works of the Muja Power Station and Collie Power Station after their closure. The overall objective of these efforts is to create new, high-quality blue-collar jobs in the Collie region.

The community is proud of its role in promoting Collie’s future and is very supportive of new industries in the region.

Supporting local business

Green Steel is committed to supporting the local communities in which it operates, including sourcing goods and services from local businesses wherever possible.

We will require a broad range of goods and services throughout the project development, construction and operational phases of our Collie green steel mill and Mid West DRI mill projects.

If you’re interested in providing services to Green Steel, we’d love to hear from you.

Jobs for the future

Green Steel is fully aligned with Collie’s Just Transition Plan and is working closely with the government, local stakeholders, workers and their representatives to develop and implement an effective, fair and transparent worker training and transition plan that will benefit both workers and GSWA’s operations alike.

Our Collie green steel mill is a $400m investment that will create more than 200 long-term local jobs, 2000 indirect jobs and around 600 jobs in construction.

Permanent roles at the Collie mill will include truck drivers, plant operators, crane operators, electricians, fitter and turners, roll turners, store, safety, environmental, finance, planning, logistics, and engineering, as well as specialist support and administration roles.

If you’d like to be kept up to date with Green Steel WA’s projects, like and follow our LinkedIn and Facebook pages.