Forging Western Australia's Steel Manufacturing Legacy

We're working to create a sustainable steel manufacturing industry using renewable electricity and green hydrogen for Western Australia

Bringing true green steel to WA

Green Steel of WA aims to bring true green steel manufacturing to Western Australia in an environmentally sustainable way.

We are in the process of developing two projects in Western Australia:

- A green steel recycling mill using renewable energy in the South West of WA, and

- A green hydrogen-powered facility to produce green steel from iron ore in the Mid-West of WA.

The Green Steel team is working closely with the Western Australian government to make local steelmaking a reality

Principal technology partner

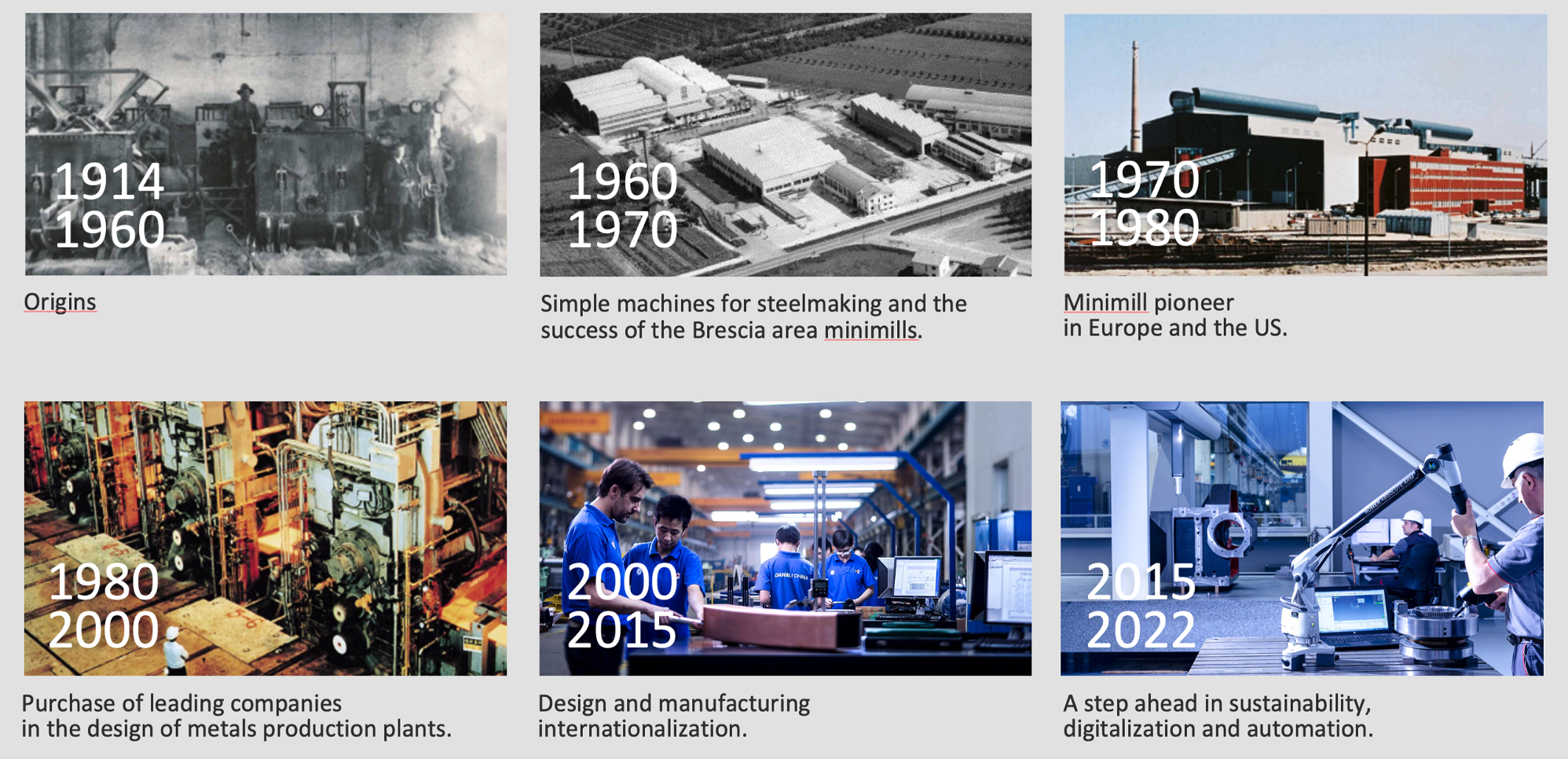

Green Steel of WA has secured a technology partnership with global steelmaking leader Danieli, which has been providing innovative steelmaking solutions around the world for more than 100 years.

During this time, Danieli has delivered more than 100 turnkey plants, giving them unparalleled experience in this field.

By combining Green Steel’s project development expertise in Western Australia with Danieli’s green steel expertise, we believe we will be able to rapidly kick-start Western Australia’s green steel and green hydrogen industries.

Our projects

Collie Green Steel Mill

Western Australia’s first green steel mill and the cleanest and most efficient in Australia

Green Steel is in the advanced stages of development and proceeding towards a final investment decision for Western Australia’s first steel mill.

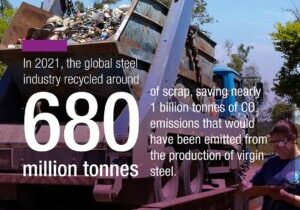

The Collie-based green steel recycling mill will convert Western Australian scrap steel into rebar for local and international consumption.

The plant will be WA’s first steel mill and the cleanest and most efficient mill in Australia.

Construction of the plant is expected to commence in late 2024, with early operations beginning in 2026. The mill will be located in the town of Collie, 220km south of Perth.

FID 2024, Operational 2026

Mid West DRI Plant

The key to unlocking Western Australia’s true green steel and green hydrogen industries

Green Steel’s green hydrogen direct-reduced iron (DRI) plant in WA’s Mid West will convert Western Australian iron ore using green hydrogen to produce green HBI for export.

The plant is based on the world’s most advanced, commercially proven hydrogen DRI technology which can operate on both green hydrogen as well as natural gas, seamlessly transitioning between the two.

This will allow the plant to begin operations on natural gas (producing just 30% of the CO2 of a conventional blast furnace) and transition to green hydrogen.

With an expected green H2 demand of up to 140,000 tonnes per year, Green Steel’s Mid West plant is the key to unlocking WA’s green hydrogen industry.

The project is expected to take a final investment decision in 2025 with operations beginning in 2028.